On May 31, four Japanese companies including Tokyo-based construction contractor Kajima announced that they developed an innovative concrete formwork method designed to reduce labor requirements. This new method, named the "Single-Pipe Formwork System," utilizes aluminum materials, achieving lighter and fewer pipes compared to traditional methods, while also simplifying construction procedures. This innovation is said to improve efficiency by approximately 20%, significantly reduce physical strain on skilled workers, and shorten construction time. It marks the first groundbreaking advancement in formwork technology in about 70 years since traditional techniques began spreading in the 1950s.

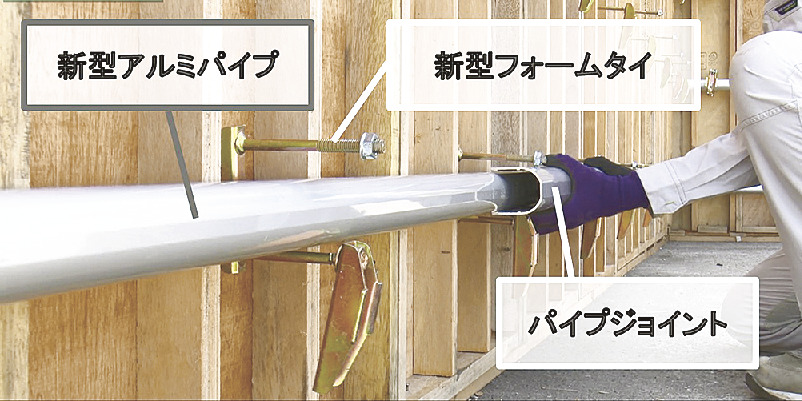

The new system is composed of aluminum pipes, form ties, and pipe joints. The newly designed aluminum pipes are significantly lighter compared to the steel pipes used in the traditional method. Although the number of pipes used is halved—from two to one per set—the new design maintains high strength. The U-shaped form ties allow aluminum pipes to be placed on the lower bolts, eliminating the need for workers to support the pipes with one hand during assembly and disassembly, enabling safer and more stable construction with both hands.

The pipe joints that connect the aluminum pipes are designed for easy installation—just by placing them over the ends and fitting them together—embodying the principles of lightness, simplicity, and speed. This design reduces the physical burden on workers and enhances safety during transportation. The lightweight materials also reduce CO2 emissions from transportation by half. Moreover, aluminum's high recyclability helps reduce industrial waste, contributing to lower environmental impact.

As of the end of May, Kajima had already implemented the new method at twelve construction sites nationwide. At a site in Tokyo, the total weight of the pipes lifted was reduced by approximately 56% compared to the traditional method, and efficiency improved by about 20%. (2024/06/03)