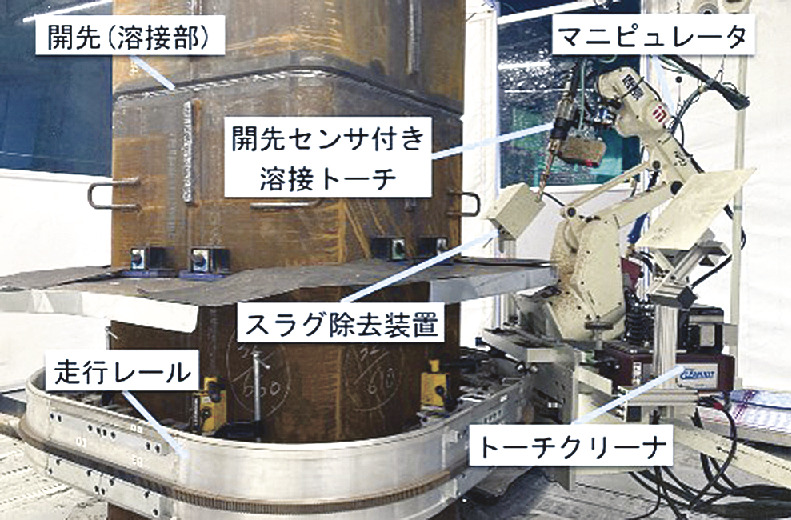

Japanese construction company Kajima Corporation has developed a manipulator-type on-site welding robot designed to fully automate the repetitive tasks involved in all-around welding for large steel columns. This new robot incorporates advanced features, including a groove sensing function and a slag removal function, building upon its existing welding robot technology. The robot can automatically measure the groove shape of the column welds, generating welding parameters such as the number of layers, welding paths, and welding speed based on the measurements. Additionally, manual slag removal is entirely eliminated, significantly boosting productivity.

The robot can perform a sequence of operations—groove measurement, welding, and slag removal—in full automation, enabling continuous operation both day and night. Operators can work remotely from the robot, managing multiple units simultaneously while performing other tasks. The manipulator, equipped with six-axis mobility, moves along tracks installed around the column, dividing the entire circumference into eight segments for automated welding. A tool changer function allows the manipulator to switch seamlessly between welding and slag removal tools, achieving complete automation of welding for a single column.

The new robot has been deployed on a trial basis at a building construction site in Yokohama, where it is used to weld certain large steel columns. The results confirm that the robot delivers fully automated welding with quality equivalent to or exceeding that of skilled human operators, as verified by ultrasonic testing and visual inspections. (2024/11/12)